Review and manipulate previously saved VERICUT 3D CNC machine simulations of your NC part programs anywhere. With VERICUT Reviewer on the iPad, shop floor personnel and other production staff can view 3D animations of CNC machining processes at the machine tool, during meetings, or at any other location. There is no need to visit the programming office or an engineering workstation to view an NC program being simulated on a virtual CNC machine.

IMPORTANT

VERICUT 7.3.x Software is required to create a “Reviewer” file. A Reviewer file can be saved at any point in a VERICUT session. It can be transferred to the VERICUT Reviewer App through iTunes, Dropbox for iPad App, or email.

SIMULATION ANALYSIS

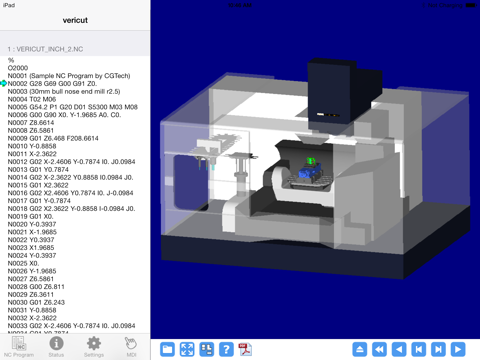

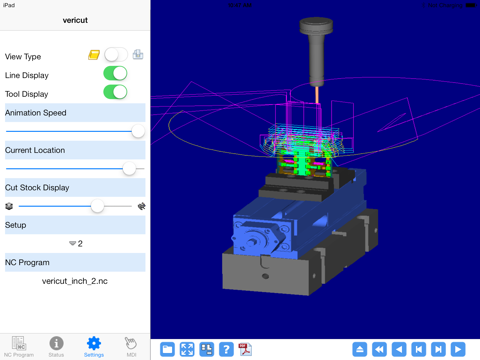

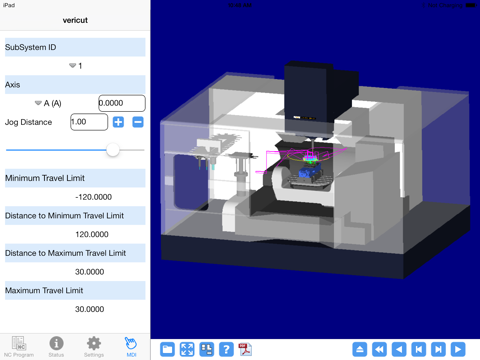

Intuitive touch controls and navigation make it easy to rotate, pan and zoom to view machining operations from any perspective as they are being simulated. A status display shows important information such as machining time, spindle speed, feed rate, tool number, cutter compensation, and more. The NC Program view displays the same lines of post-processed code that will drive the real CNC machine. VERICUT’s simulation moves according to the NC code the same as the CNC machine, so virtual machining exactly mimics real machining.

The VERICUT Reviewer App allows you to select and closely examine specific sections of NC code where a potential problem might exist. Step forward and backward through the selected NC program lines and closely evaluate machining actions.

A VERICUT report PDF file containing information about cutting tools, job setup, machining instructions and other information can be automatically packaged within each saved Reviewer session. The PDF is easily viewed anytime during review of machining operations, using standard iPad PDF viewing features. VERICUT report PDFs are automatically generated during VERICUT simulations.

BENEFITS

• Reduce errors in the workshop by visually communicating CNC machining processes

• Give machine operators greater confidence when running new or complex machining operations

• Improve efficiency by quickly referencing current production jobs in meetings, in the factory, during hallway discussions, virtually anywhere.

SAMPLES

Learn more and get free sample files from http://www.cgtech.com/ipad